Indexable Drills

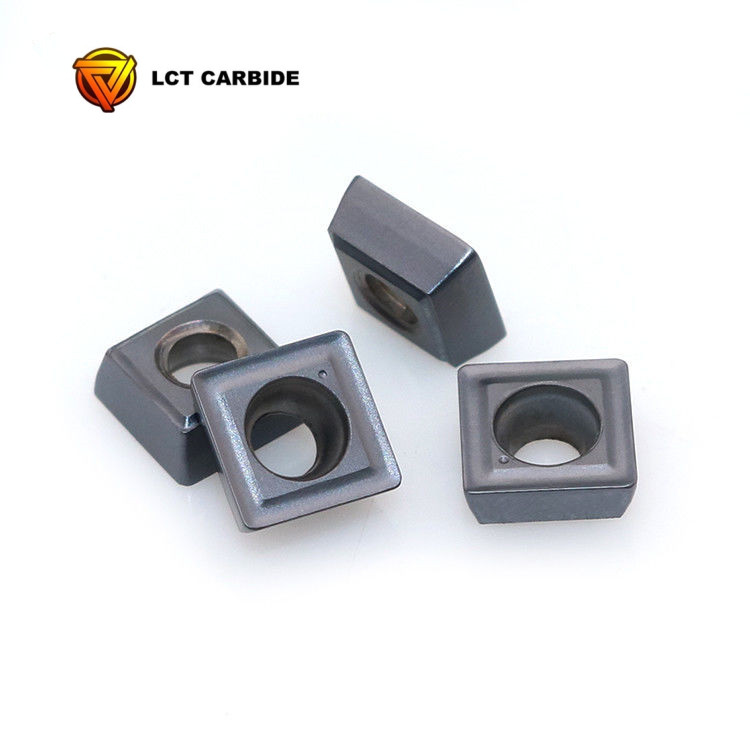

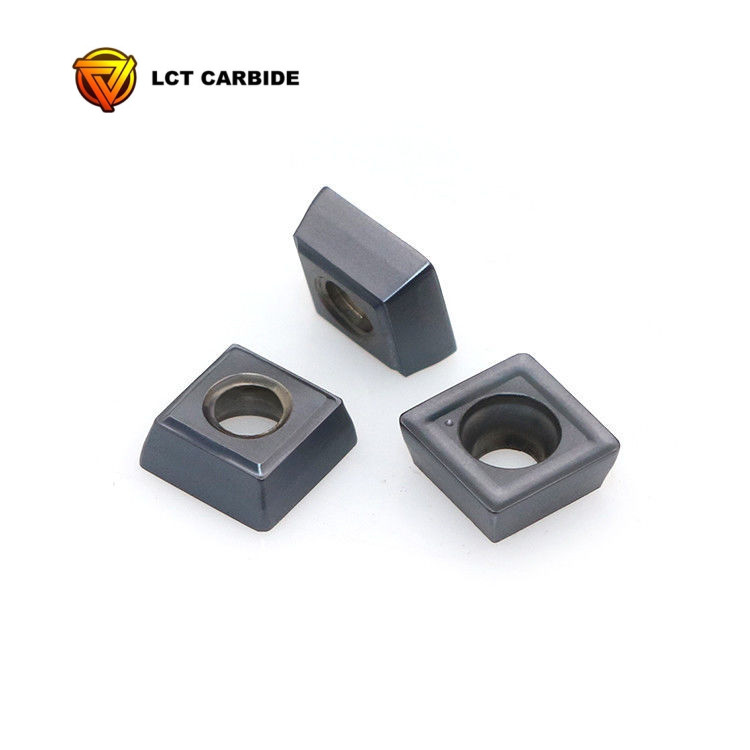

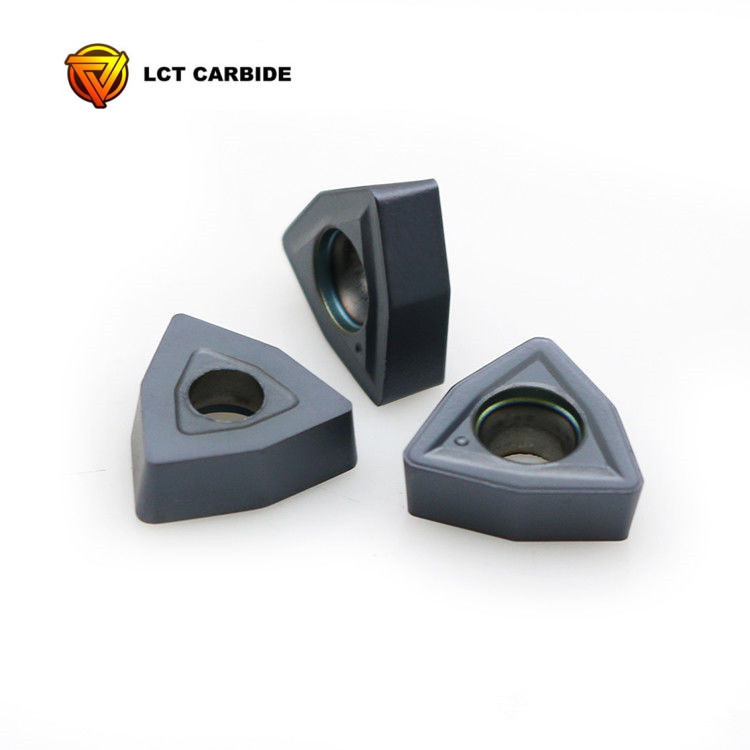

SPGT060204 U-Drill Inserts/Carbide Drill Inserts/CNC Indexable Milling Cutter/PVD Coating

- Product description: Quality Carbide Drill Inserts manufacturers & exporter - buy SPGT060204 Carbide Drill Inserts CNC Indexable Milling Cutter PVD Coating from China manufacturer.

Zhuzhou Lingchuang Cemented Carbide Tools Co.,Ltd (here in after reffered as LCT) is a Chinese company which established in 2008 located in Zhuzhou City,Hunan province,China where is famouse in the world for its tungsten carbide industry. lCT is a professional manufacturer of Cutting Tools and Carbide material. it has specialized in the Design and Manufacture of High-Quality Cutting Tools & Carbide material. Having more than thousands different kinds of items and huge stocks. Sieeso has a key product line for tools and material with advanced equipment and instruments.

50% of our products provide as OEM project for world-class cutting companies and 50% to do as our own brand. Our products have been sold to all-around the world, Such as Russian, Turkey, Europe, USA, Mexico, Vietnam, Thailand, India, Malaysia, and so on.

1 Basic Information

Material: | Tungsten Carbide | Grade: | Steel/Stainless/Cast Iron |

Chip breaker: | Process For Semi Finish , Finish And Rough | Color: | Black/Yellow |

Size: | SPGT All Series Have Mould And In Stock | Coating: | CVD/PVD |

Place of Origin: | Zhuzhou, China | Certification: | ISO9001:2015/ CQC |

Description: | l For machining of steel, stainless steel, cast iron and heat-resistant alloys. l Drilling bodies with PVD coated surfaces. l Big chip pocket for better chip removal. l Optional adapter for inner cooling in conventional machines. l Diameter range 13.0–50.0 mm | ||

Application: | SPGT types U drill tools U-drilling insert/ indexable drill inserts series It's suitable for the processing of materials of carbon steel, alloy steel and austenitic stainless steel with high cutting efficiency under stable working conditions. | ||

Workpiece: | Finishing and semi-finishing of stainless steel, steel , hard steel , cast iron , ect. | ||

2 Specification

TYPE | Dimensions | ||||

L | Θ I.C | S | Θ d |

r

| |

SPGT050204-DPMX/DMM | 5 | 5 | 2.38 | 2.2 | 0.4 |

SPGT060204-DPMX/DMM | 6 | 6 | 2.38 | 2.6 | 0.4 |

SPGT07T308-DPMX/DMM | 7.94 | 7.94 | 3.97 | 2.8 | 0.4 |

SPGT090408-DPMX/DMM | 9.8 | 9.8 | 4.76 | 4.2 | 0.8 |

SPGT110408-DPMX/DMM | 11.5 | 11.5 | 4.76 | 4.4 | 0.8 |

SPGT140512-DPMX/DMM | 14.3 | 14.3 | 5.2 | 5.75 | 1.2 |

SPGT 050204 DMM/DPMX | Suitable for diameter 13- 16MM fast drill. |

SPGT 060204 DMM/DPMX | Suitable for diameter 16.5- 22MM fast drill. |

SPGT 07T308 DMM/DPMX | Suitable for diameter 22.5- 29MM fast drill. |

SPGT 090408 DMM/DPMX | Suitable for diameter 29.5- 36MM fast drill. |

SPGT 110408 DMM/DPMX | Suitable for diameter 36.5- 43MM fast drill. |

SPGT 140512 DMM/DPMX | Suitable for diameter 44- 50MM fast drill. |

3 Grade Information

Grade No | Application | |

CVD COATING |

DH7442

| CVD coated P20–P40/K20–K40 carbide substrate for operation with higher cutting speed and feed rate in steel and cast iron. |

DH3050 | CVD coated K20–K35 carbide substrate. Optimized for medium to roughing operation of cast iron and Steel. Good wear resistance and toughness at higher cutting speed. | |

PVD COATING | DW5025

| PVD coated M10–M25/P10–P30 carbide substrate for finishing to medium application of stainless steel and steel (milling). Good wear resistance in a wide application field. |

DW2025

| PVD multilayer coated P10–P30/M20–M40/S15–S25 carbide substrate for finishing to medium application of stainless steel, super alloy and steel (milling). Good wear resistance and thermal stability in a wide application field. | |

DW4050

| PVD coated M25–M40/P25–P35 carbide substrate for steel and stainless steel. Especially for inner insert at drilling operation.

| |

Uncoated carbide | DD201 | Uncoated N10–N30/K10–K30 carbide substrate for medium application in aluminum and other material. |

4 Chip Breaker

Chip breaker | Application |

DPMX | For machining of steel, stainless steel and cast iron |

DMM | For machining of steel, stainless steel and heat-resistant alloys. |

PG | For machining of steel and cast iron |

D | For machining of steel, stainless steel and cast iron. |

53 | For machining of steel, stainless steel, cast iron and non-ferrous metals |

5 Payment & Shipping Terms

Minimum Order Quantity:

|

10PCS |

Price:

|

Negotiation |

Packaging Details: | Inner plastic box ; outside wooden box or as customer's special requirements. |

Payment Terms: |

T/T,WesternUnion,Paypal, MoneyGram,Alipay,L/C, D/A, D/P |

Delivery Time: | In stock 3 days,out of stock 15 working days | Supply Ability: | 500000pcs per month |

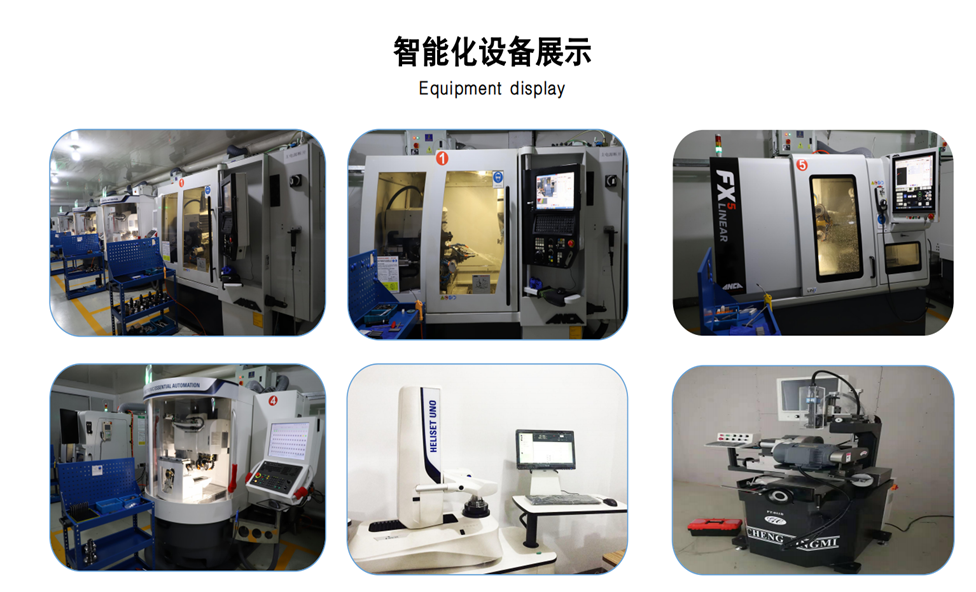

Our plants and equipments:

Contact us without any hesitate,our staff worked for 7*24 hours.

Contact Person: | Jennifer |

Email: | |

Tel/Wechat: | +86-186 5202 9326 |

Address: | D3-05 Automotive Component Park, No. 1986 Taishan Road Zhuzhou, Hunan, China |

Wechat:

Drop Us a Line

Categories

Latest News

Contact Us

Contact: Jennifer

Tel: +86-731-22481009

Fax: 0731-22481019

Email: jennifer@lctcarbide.com

Add: D3-05 Automotive Component Park, No. 1986 Taishan Road Zhuzhou, Hunan, China