Solid Carbide Endmill

4 Flutes Solid Carbide Endmill/Corner Radius/Round Nose AlTIN Coating /60-65HRC

- Product description: Solid Carbide Cutting Tool Milling Cutter Manufacturer Tools CNC End Mill, US $ 2 - 2.11, Zhuzhou, China, ,OEM, End Mill, Milling Cutter. Source from Zhuzhou Lingchuang Cemented Carbide Tool Co., Ltd

Zhuzhou Lingchuang Cemented Carbide Tools Co.,Ltd (here in after reffered as LCT) is a Chinese company which established in 2008 located in Zhuzhou City,Hunan province,China where is famouse in the world for its tungsten carbide industry. lCT is a professional manufacturer of Cutting Tools and Carbide material. it has specialized in the Design and Manufacture of High-Quality Cutting Tools & Carbide material. Having more than thousands different kinds of items and huge stocks. Sieeso has a key product line for tools and material with advanced equipment and instruments.

50% of our products provide as OEM project for world-class cutting companies and 50% to do as our own brand. Our products have been sold to all-around the world, Such as Russian, Turkey, Europe, USA, Mexico, Vietnam, Thailand, India, Malaysia, and so on.

Products Description

l Hardness: HRA 91.8-92.5

l Work piece: HRC45-50 HRC55-60 HRC65 HRC68

l Helix angle: 30°-45 °

l Diameter of cutting edge: 0.2-0.9 mm; 1-20 mm

l Diameter of rods: 4-20 mm

l Length: 50-100 mm

l Cutting Form: Flat, Square, Ball nose, Corner Radius, Taper Flute, etc

l Flutes No: 1-8

l Customized Available

Specifical of our carbide endmills:

LCT ITEMS | Straight End Milling Cutter – 4 Flutes | ||||||

Diameter 直径 | Total Length 总长度 | Rod Diameter 杆径 | Cut Length 切割长度 | Price 价格 USD/pcs | |||

45HRC | 55HRC | 65HRC | |||||

D1*D4*50L-4F | 1mm | 50mm | 4mm | 3 | |||

D2*D4*50L-4F | 2mm | 50mm | 4mm | 6 | |||

D3*D4*50L-4F | 3mm | 50mm | 4mm | 7.5 | |||

D4*D4*50L-4F | 4mm | 50mm | 4mm | 10 | |||

D5*D5*50L-4F | 5mm | 50mm | 5mm | 13 | |||

D6*D6*50L-4F | 6mm | 50mm | 6mm | 15 | |||

D8*D8*60L-4F | 8mm | 60mm | 8mm | 20 | |||

D10*D10*75L-4F | 10mm | 75mm | 10mm | 25 | |||

D12*D12*75L-4F | 12mm | 75mm | 12mm | 30 | |||

D16*D16*100L-4F | 16mm | 100mm | 16mm | 45 | |||

D20*D20*100L-4F | 20mm | 100mm | 20mm | 45 | |||

D2*D4*75L-4F | 2mm | 75mm | 4mm | 6 | |||

D3*D3*75L-4F | 3mm | 75mm | 3mm | 9 | |||

D4*D4*100L-4F | 4mm | 100mm | 4mm | 20 | |||

D5*D5*100L-4F | 5mm | 100mm | 5mm | 25 | |||

D6*D6*100L-4F | 6mm | 100mm | 6mm | 30 | |||

D8*D8*100L-4F | 8mm | 100mm | 8mm | 35 | |||

D10*D10*100L-4F | 10mm | 100mm | 10mm | 40 | |||

D12*D12*100L-4F | 12mm | 100mm | 12mm | 45 | |||

D16*D16*150L-4F | 16mm | 150mm | 16mm | 65 | |||

D20*D20*150L-4F | 20mm | 150mm | 20mm | 70 | |||

Super Raw Material

Item | HRC50 | HRC55 | HRC60 | HRC65 |

Grade | YG10X | YL10.2 & WF25 | Germany K44 &K40 | Sandvik H10F |

Details | Grain size 0.7um, Co10%, Flexural strength 3320N/mm2 | Grain size 0.6um, Co10%, Flexural strength 4000N/mm2 | Grain size 0.5um, Co12%, Flexural strength 4300N/mm2 | Grain size 0.5um, Co10%, Flexural strength 4300N/mm2 |

Super Coating

Coating Classifying and Advantage | |||||

Item | Coating Type | AlTiN | TiAlN | TiSiN | NaNo |

Characteristic | Hardness(HV) | 3300 | 2800 | 4300 | 42(GPA) |

Thickness(UM) | 2.5-3 | 2.5-3 | 3 | 3 | |

Oxidation Temp.(°C) | 900 | 800 | 1000 | 1200 | |

Friction Coefficient | 0.35 | 0.3 | 0.25 | 0.4 | |

Color | Black | Dark Purple | Copper | Blue | |

Advantages | High heat stability | Normally cutting | Suitable for heavy cutting, and high hardness cutting | For high precision Cutting | |

Suitable for high speed, dry cutting | Suitable for cutting mould steel, stainless steel | Suitable for high hardness cutting, mould steel processing | |||

Most suitable for carbide cutting tools, turning insert | |||||

Our advantage:

1.Provide a high feed speed and improve the process efficiency.

2.Suitable for high hardness steel and can keep a long service life.

3. Material Solid carbide and whole forging processing make the turning tool with long service life, better wear-resistance, strength and rigidity, high working efficiency.

4. Unique surface treatment with good antiseptic property.

5. High seismic resistance performance, which can improve the surface finish degree of the workpiece.

6. Competitive price and fast delivery will save the time and cost.

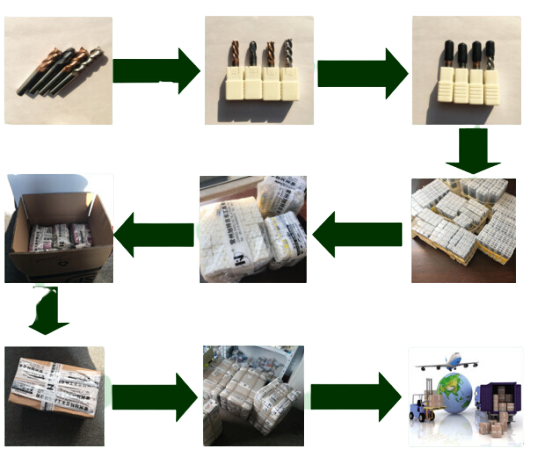

Our Package

Shipping

Payment

Our Service

Pre-sale Service:

We have professional sales staff and application engineer; they can do the drawing confirmation and previous communication about the production and design of the tools based on your special requirements.

Sales Service:

Our professional sales staff will communicate and make reasonable production schedules based on your order requirements and delivery time. Meanwhile, sales staff can also know the status of orders anytime and communicate with you timely.

After-sale Service:

Our professional sales staff will make return visits regularly, to know all the situation you have encountered during the application of the ordered products and then feedback to company. At the same time, we will arrange the returning and changing of the products timely if they have possible quality problems.

Technical Support:

We have a number of veteran tooling design engineers, who can offer reasonable suggestions on the working procedure of your products, help you to improve the production efficiency. More importantly, we can design the products according to your requirements.

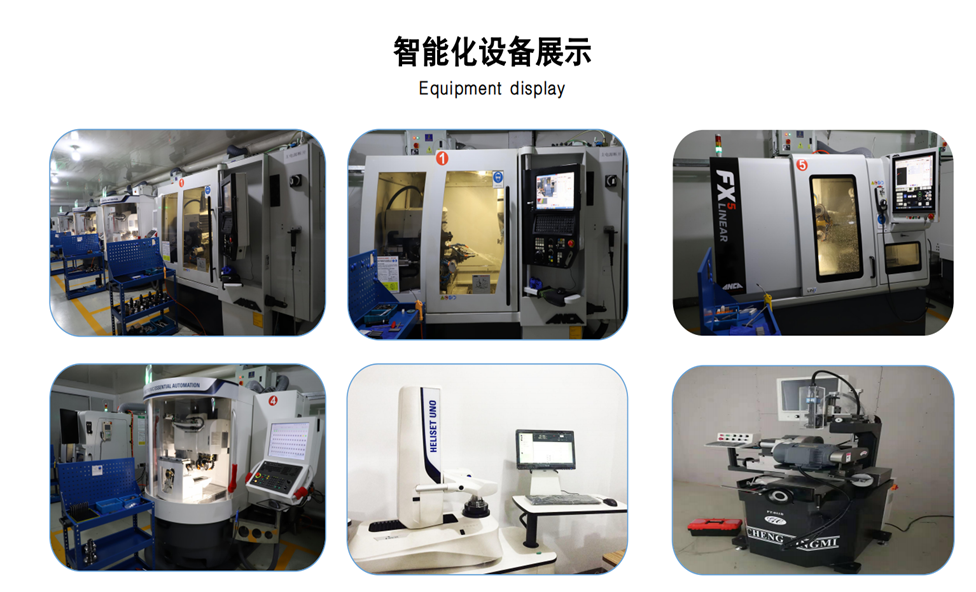

Our plants and equipments:

Contact us without any hesitate,our staff worked for 7*24 hours.

Contact Person: | Jennifer |

Email: | |

Tel/Wechat: | +86-186 5202 9326 |

Address: | D3-05 Automotive Component Park, No. 1986 Taishan Road Zhuzhou, Hunan, China |

Wechat:

Drop Us a Line

Categories

Latest News

Contact Us

Contact: Jennifer

Tel: +86-731-22481009

Fax: 0731-22481019

Email: jennifer@lctcarbide.com

Add: D3-05 Automotive Component Park, No. 1986 Taishan Road Zhuzhou, Hunan, China