ISO general turning inserts

SN**type- CNC Turning Inserts With Excellent Performance

- Product description: Quality Carbide Turning Inserts manufacturers & exporter - buy Cnc Turning Tools Inserts SNMG from China manufacturer. Top 10 carbide insert cutting tool manufacturers & wholesaler in China

Zhuzhou Lingchuang Cemented Carbide Tools Co.,Ltd (here in after reffered as LCT) is a Chinese company which established in 2008 located in Zhuzhou City,Hunan province,China where is famouse in the world for its tungsten carbide industry. lCT is a professional manufacturer of Cutting Tools and Carbide material. it has specialized in the Design and Manufacture of High-Quality Cutting Tools & Carbide material. Having more than thousands different kinds of items and huge stocks. Sieeso has a key product line for tools and material with advanced equipment and instruments.

50% of our products provide as OEM project for world-class cutting companies and 50% to do as our own brand. Our products have been sold to all-around the world, Such as Russian, Turkey, Europe, USA, Mexico, Vietnam, Thailand, India, Malaysia, and so on.

1 Basic Information

Basic information | |||

Material: | Tungsten Carbide | Grade: | Steel/Stainless/Cast Iron |

Chip breaker: | Process For Semi Finish , Finish And Rough | Color: | Black/Yellow |

Size: | SNMG | Coating: | CVD/PVD |

Place of Origin: | Zhuzhou, China | Certification: | ISO9001:2015/ CQC |

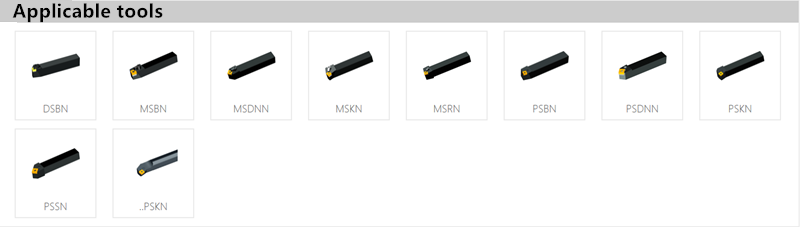

Description: | One type of well commented carbide TURNING INSERTS, it is very popular among our customers all over the world. Suitable to the holders of DSBNR/L PSBNR/L PSDNN PSKNR/L PSSNR/L MSBNR/L MSRNR/L MSDNN PSKNR/L. And this type has samples in stock commonly. Have different choices for dimensions, chip breakers and grade, normally it's 12 size, with different corner radius. | ||

Application: | Finishing and semi-finishing CNC machinery. | ||

Workpiece: | Finishing and semi-finishing of stainless steel, steel , hard steel , cast iron , ect. | ||

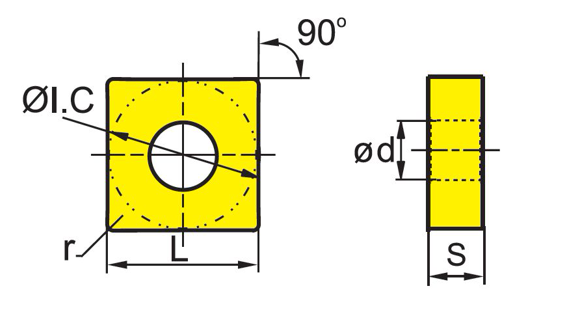

2 Specification

TYPE | Dimension | ||

S | Θ d | r | |

SNMG090304-DPF/DPMX/DPM/DTR | 3.18 | 3.81 | 0.4 |

SNMG090308- DPF/DPMX/DPM/DTR | 3.18 | 3.81 | 0.8 |

SNMG090312- DPF/DPMX/DPM/DTR | 3.18 | 3.81 | 1.2 |

SNMG120404- DPF/DPMX/DPM/DTR | 4.76 | 5.16 | 0.4 |

SNMG120408- DPF/DPMX/DPM/DTR | 4.76 | 5.16 | 0.8 |

SNMG120412- DPF/DPMX/DPM/DTR | 4.76 | 5.16 | 1.2 |

SNMG120416- DPF/DPMX/DPM/DTR | 4.76 | 5.16 | 1.6 |

SNMG150608- DPF/DPMX/DPM/DTR | 6.35 | 6.35 | 0.8 |

SNMG150612- DPF/DPMX/DPM/DTR | 6.35 | 6.35 | 1.2 |

SNMG190612- DPF/DPMX/DPM/DTR | 6.35 | 7.94 | 1.2 |

SNMG190616 | 6.35 | 7.94 | 1.6 |

SNMG250724 | 7.94 | 9.12 | 2.4 |

SNMG250924 | 9.52 | 9.12 | 2.4 |

3 Grade Information

| No | Grade No | Application | Compatible Grade No | Coating Type | |||

| 1 | DW5025 | P10-P25, M10-M25 - Finishing and semi-finishing of steel, stainless steel and high-temperature alloys. | YBG202 GC1020 PC230 PR630 IC908 VP15TF | PVD | |||

| 2 | DH1025 | P20-P25 - Medium to roughing of steel and casting steel. | YBC251 GC4015 GC4225 TT1500 IC9250 T9015 T9025 | CVD | |||

4 Chip Breakers

DPM | M | ap=0.059~0.197(inch) fn=0.006~0.020(inch/r) | Main chip breaker for medium machining with continuous or interrupted cut of steel and stainless steel. | FOR SEMI-FINISHING |

DPMX | M | ap=0.059~0.197(inch) fn=0.006~0.020(inch/r) | It’s suitable for semi-finishing under unfavorable conditions. Also good for machining cast iron with low cutting force. |

FOR SEMI-FINISHING |

DPM | M | ap=0.059~0.197(inch) fn=0.006~0.020(inch/r) | Main chip breaker for medium machining with continuous or interrupted cut of steel and stainless steel. | |

DTR/ Double side | M | ap=0.118~0.472(inch) fn=0.012~0.031(inch/r) | Recommended chipbreaker for light-load roughing of P-kind and K-kind materials. | FOR LIGHT-LOAD ROUGHING |

DTR/single side | M | ap=0.118~0.591(inch) fn=0.012~0.031 (inch/r) | Positive chip breaker with strong cutting edge for light to medium rough machining of steel and cast iron. | FOR ROUGHING |

5 Payment & Shipping Terms

Minimum Order Quantity:

|

10PCS |

Price:

|

Negotiation |

Packaging Details: | Inner plastic box ; outside wooden box or as customer's special requirements. |

Payment Terms: |

T/T,WesternUnion,Paypal, MoneyGram,Alipay,L/C, D/A, D/P |

Delivery Time: | In stock 3 days,out of stock 15 working days | Supply Ability: | 500000pcs per month |

6 What makes LCT Carbide Top on this field

Quick Response | Inquiry will be replied within 8 hours. |

High Quality | Well-trained workers and more than 13 years’ experience. Regular orders from our customers all over the world, already very stable quality. |

Competitive Price | Directly from factory to save your cost. |

Short Lead Time | Being efficient: 3 days for samples and 10-35 days for bulk orders. |

Flexibility | Small orders are acceptable for quick delivery and to help you reduce stock cost. Have different sizes, coating color have yellow, black, purple, grey, broze and different chip breakers for choice. |

OEM | Customized production according to your drawings, samples or designs. |

Our plants and equipments:

Contact us without any hesitate,our staff worked for 7*24 hours.

Contact Person: | Jennifer |

Email: | |

Tel/Wechat: | +86-186 5202 9326 |

Address: | D3-05 Automotive Component Park, No. 1986 Taishan Road Zhuzhou, Hunan, China |

Wechat:

Drop Us a Line

Categories

Latest News

Contact Us

Contact: Jennifer

Tel: +86-731-22481009

Fax: 0731-22481019

Email: jennifer@lctcarbide.com

Add: D3-05 Automotive Component Park, No. 1986 Taishan Road Zhuzhou, Hunan, China